LOCA (Loss of Coolant Accident) Testing

Nuclear reactors generate heat internally, to remove this heat and convert it into useful electrical power, a coolant system is used. If this coolant flow is reduced, or lost altogether, the nuclear reactor’s emergency shutdown system is designed to stop the fission chain reaction.

This is a term used in the nuclear industry to describe an event in which a nuclear reactor loses its coolant, which can lead to overheating and potentially serious consequences.

LOCA testing stands for “Loss-of-Coolant Accident testing.” It is a type of safety testing performed on nuclear power plant systems or accessories to assess their response to a loss of coolant accident, which is a severe hypothetical event in which the cooling capability of a nuclear reactor is compromised. LOCA testing is conducted to evaluate the behavior of safety systems and components under these extreme conditions.

LOCA, the term is used to describe an event in which a nuclear reactor loses its coolant, which can lead to overheating and potentially serious consequences.

Loss of Coolant Accident (LOCA) tests is an environmental qualification (EQ) process provide assurance that the equipment will continue to perform its intended safety function during and following a loss of coolant event.

RTRC Limited in collaboration with NPCIL (Nuclear Power Corporation of India Limited) has designed and developed LOCA (Loss of coolant accident) test facility in India for testing of the products to be used in Nuclear Reactor.

- RTRC Limited has designed & developed an integrated software-based test facility to perform the LOCA test. The system is designed for flexible test profile pressure up to 8 BAR and Temperature up to 300 Deg.C.

- The robust design of the chamber makes it unique to accommodate any bigger size objects up to dimension of 1500 mm x 1500 mm x 1500 mm.

- CRM grade chemical is used for BORIC acid solution. The duration of boric acid may have in continuous spray or at an adjustable profile mode. An automatic feed tank with a capacity of 100 liters feeds BORIC acid automatically.

- To ensure the integrity of the object during the entire period of test the facilities is equipped to energies the object with current up to 5000 amp and voltage up to 100 kV.

- Digital display parameters and integrated data logging system make it unique.

- PNG generators and diesel generators provide backup power.

- EOT crane installed for easy and safe handling.

- Well-defined SOP and high standard safety measures.

Unique Test Facilities

| Product | Specifications |

|---|---|

| ACLT (Accelerated Cable Life Test) AWTT (Accelerated Water Treeing Test) | IEEE 1407 |

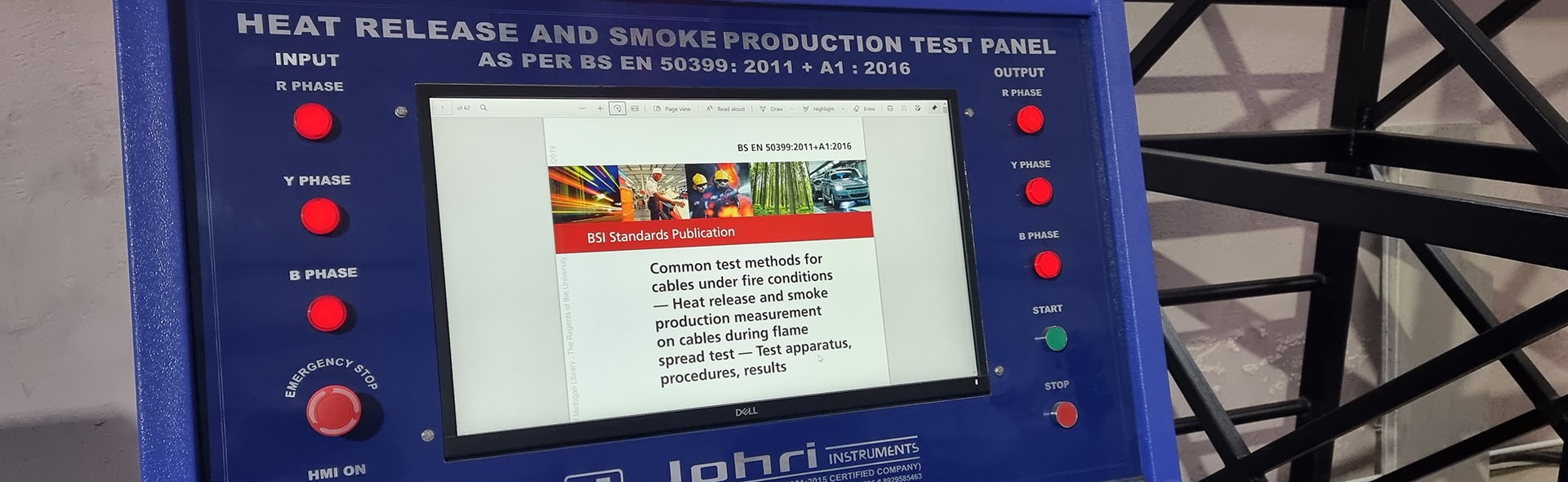

| CPR (Construction Product Regulation) | BS EN 50575, BS EN 50399 , BS EN 13501-6, BS EN 60754-2, BS EN 61034-2 |

| 66 kV Cable | IEC 60840 & IS 7098 (Part-3) |

| Elastomeric Insulated Cables for working voltages upto and including 1100V | IS 9968-1 & IEC 60502-1 |

| Elastomeric Insulated Cables for working voltages from 3.3 kV to 33 kV | IS 9968-2 & IEC 60502-2 |

| Elastomeric Insulated Flexible Cables For Use In Mines | IS 14494 |

| Oxidation Induction Time (Differential Scanning calorimeter) | ASTM D 3895 |

| Electrical Cables for photovoltaic system (Solar Cables) – Complete type tests | BS EN 50618, IEC 62930 & IS 17293 |

| Thermal Endurance (Cable Service life) | IEC 60216-1 & 2 |

| Covered Conductors for Overhead Lines- Complete type tests including Tracking Index , Slippage, Leakage Current | BS EN 50397-1 |

| Bundled assembled cores for overhead system of rated voltages 0.6/1.0 kV- Complete type tests | NFC 33-209, SANS 6100 & BS 7870-5 |

| Endurance test under Thermal & Mechanical stress | NFC 33-209 & SANS 6100 |

| Anti Rodent and Anti Termite | NPCIL specification I28.KK34.0.0.ET.PM.PR072/RDSO/SPN/TC/45 |

| Anti Rodent & Anti Termite | AAI Specification |

| UV resistance test -XENON | BS EN ISO 4892-2, ASTM G 155, UL 1581 & BS EN 50618 |

| UV resistance test -Fluorescent | BS EN ISO 4892-3 & ASTM G 154 |

| UV Resistance test – XENON – Procedure A & B | IEC 60068-2-5 |

| Toxicity Index Test | NES 713 |

| Dielectric strength retention test | NEMA WC 5 |

| Accelerated water absorption test (Electrical) | NEMA WC 70 |

| Toxicity Index test : Qualitative and Quantitative | BS EN 50305 |

| Fluorine content test | IS 17048, IEC 60840 & BS EN 50525-1 |

| Gel content test | ASTM D 2765 |

| Colour Fasteness to day light | IS 10810-18 |

| Thermosetting Insulated Fire Survival Cables for Fixed Installation having Low Emission of Smoke and Corrosive Gases when Affected by Fire for Working Voltages upto and including 1100 Vac and 1500 Vdc | IS 17505-1 |

| Elastomeric Insulated Cables with limited circuit integrity when affected by fire. | IS 16246 |

| Water Penetration Test | IEC 60502-2 |

| Ozone Resistance Test | IEC 60811-403 |

| Measurement of Low Level of Halogen Content (Chlorine/Bromine/Fluorine/Iodine) | IEC 60754-3 |

| Drill fluid test | IEC 60092-360 |

| Ester Oil Tests | IS 16899 |

Other Services

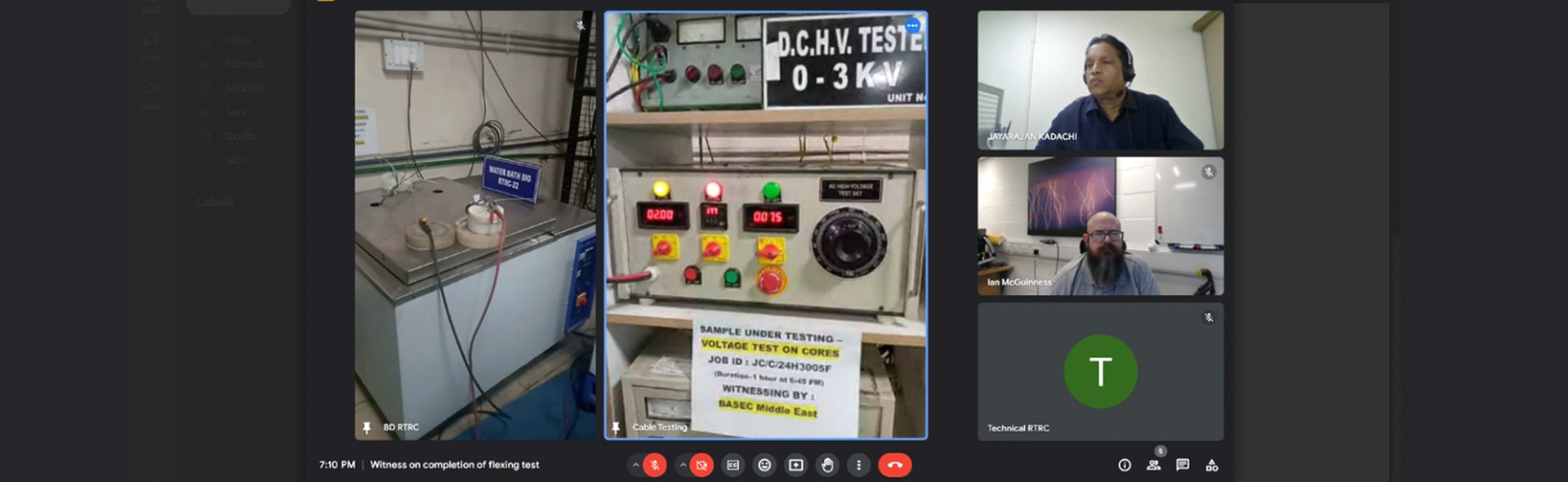

We are an internationally recognized testing laboratory, providing high-quality testing services to clients in over 20 countries.